28 Hook TC

We are constantly striving to improve our products to meet the demands of our customers.This time, the three requirements we received and were able to fulfill at the same time were: (1) weight reduction (2) compatibility with highly gaseous carbonated beverages and (3) opening sound.Reducing the weight of the cap can lead to a reduction of several thousand tons of CO2 emissions per year, including a reduction in the amount of raw materials required for its manufacture.

In addition, the new cap has a seal that withstands the recent “strong carbonation” boom, while maintaining the easy-opening of the conventional cap.And yet, there were a wide variety of factors required, such as the opening sound that gives a sense of carbonation.

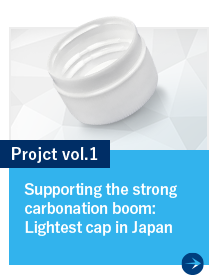

Maximized pressure resistance performance while reducing weight

Among the various challenges, the first thing we set out to do was to reduce the weight of the cap.

Since the band at the bottom of the cap has little effect on performance, we focused on weight reduction there.On the other hand, the screw in the middle of the cap has been strengthened to prevent the cap from lifting due to the increase in internal pressure caused by strong carbonation.During the development process, we encountered a problem with a reduction in the cap opening noise.After a year of repeated trial and error, we were finally able to determine the cause of the problem and designed a sealing profile that allows gas to escape all at once when the bottle is opened.This is how we were able to develop the lightest carbonated beverage cap in Japan.

Project Review