28 Hook Aseptic ML Cap

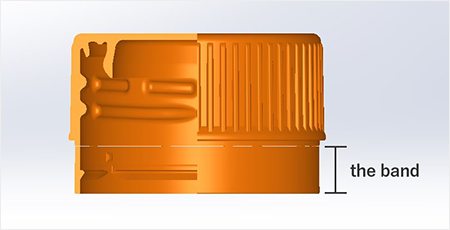

We have long been working to reduce the weight of our products to reduce the amount of resin used, with the aim of reducing environmental impact. This time, we have developed a new lightweight cap by changing the shape of the band from the conventional cap for products that can be sold after being heated. The key points of the development are as follows.

(1) 10% or more weight reduction from conventional products

(2) No change in the customer’s capping equipment

(3) Equivalent capping performance to conventional products

Achieving these points was a major barrier to commercialization.

Achieved weight reduction while maintaining cap performance!

Among the issues that emerged during the development of this product, the particularly difficult point was to achieve both cap formability and cap performance by reducing the weight of the band. The lightening of the band caused unexpected challenges in cap formability. In response to this issue, we had to review the cap shape and mold structure, which made it very difficult to achieve compatibility with cap performance. We finally managed to overcome the challenges by gathering the people involved in the development process many times to hold repeated discussions and by performing trial and error again and again. Thanks to our efforts, we were able to achieve a weight reduction of more than 10% from the existing product, which was one of the initial points to be achieved, without making any changes to the customer’s capping equipment. We ultimately exceeded the target with a weight reduction of 14%.

Project Review