29 Screw hinge valve

In recent years, the seasoning & condiment industry has been seeking to improve the usability of caps, such as ease of pouring and dripping performance, in addition to sealing, which is an essential role of caps.For this reason, silicone valves are increasingly being used for spouts. But the unit cost of the cap is high due to the high cost of the silicone material, the need for a separate part to secure the silicone valve, and the need for a separate device to incorporate the cap. So we changed the valve material from silicone to elastomer, and dissimilar material molding(co-injection,double-shot injection) technology was adopted to enable integrated molding of the valve and cap.This has resulted in the productization of a new valve cap with stable performance and greatly reduced production costs.

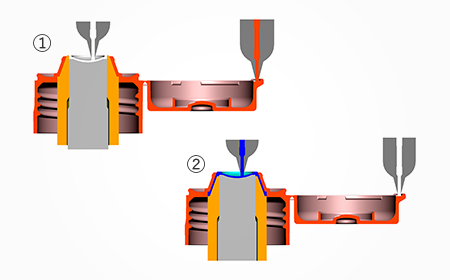

(①1st material injection, ②2nd material injection)

Achieves both pourability and dripless performance

A valve cap with a thin wall thickness facilitates valve deformation during dispensing, resulting in a smaller dispensing force and better dispensing performance.On the other hand, thicker valves allow the liquid to be shut off more quickly, resulting in better run-off after dispensing.In order to achieve both of these contradictory abilities, the base of the valve is made thinner and only in the center and where the liquid is cut is made thicker, thereby achieving both discharge and dripping performance requirements.

Project Review