28 Screw AN

Screw caps for glass bottles are generally sealed with a soft sealing material such as packing, which is pressed onto the glass finish. For medicinal liquor, which is consumed in appropriate quantities every day, the repeated use of the bottle has caused the glass finish to become dirty and the sugar content in the liquid to harden, making it difficult to open the bottle. Therefore, we have developed a new product that uses a cap with an inner plug with excellent liquid drainage characteristics. It is easy to remove when disposing of the bottle, and also easy to adjust the amount of liquid when measuring.

In addition, to prevent complications on the customer’s filling line, this product is set in the glass finish with the inner plug by simply wrapping the cap around the bottle, and when used, the cap and inner plug disengage as the bottle is opened, leaving only the inner plug in the glass finish.

New technology born from a break with existing concepts

Ease of pouring

In addition to the selection of an optimal spout shape that matches the type of liquid contained in the bottle, a hole shape has been adopted to prevent pulsation when dispensing a small amount of liquid and to facilitate adjustment of the liquid volume. Before fabricating the mold for the cap, we selected the shape through trial and error with the customer using a 3D printer modeling product.

Ease of sorting

We have devised the selection of materials for the inner plug and the shape of the mating part so that even the elderly or women with limited strength can easily sort the bottles.

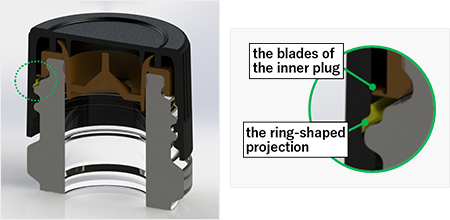

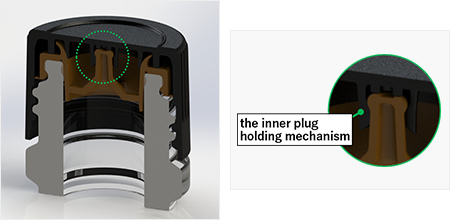

Retaining mechanism of inner plug

At the beginning of the development, we had been promoting the development based on our existing mechanism “to hold the inner plug by hooking a ring-shaped protrusion on the inner surface of the cap to a vane on the outer circumference of the inner plug.” However, the blades of the inner plug were repeatedly rubbed against the ring-shaped projection of the cap, causing dust to be generated, and the sound of the rubbing could cause users to mistake the cap for being closed. We felt the customer’s strong commitment to eliminating the sound, and by breaking away from existing concepts, we were able to develop a new mechanism for retaining the inner plug and preventing the sound, which was adopted.

Project Review

We are very grateful to those involved in the development of the product.