38PE-M CAN DP5 P.P.CAP

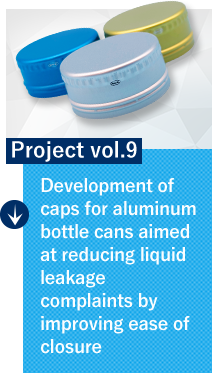

Aluminum bottle cans (*1), which are still widely loved today, began being sold in the market around 2000. Our caps continue to evolve daily to improve functionality such as ease of opening and leak resistance. Development of this product began after receiving a request from a major beverage brand that wanted to eliminate the approximately ten-plus liquid leakage complaints that occur annually. Analysis of complaint content received by consumer consultation centers revealed that many cases involved liquid leaking and staining valuable belongings when consumers put the cans in their bags without fully closing the caps after drinking.

*1 Beverage cans equipped with caps having reseal functionality

Improving ease of closure through cap shape design innovations

Subsequent investigation results confirmed that insufficient cap closure occurs because resistance when closing the cap suddenly increases due to variations in bottle finish shape and capping conditions. To solve this problem, after repeatedly prototyping and evaluating various cap shapes, we ultimately succeeded in developing a specification that improved ease of closure through the following shape innovations.

Improved grip performance

We improved grip performance when grasping the cap with fingers by increasing the number of ridges and grooves on the cap’s side surface.

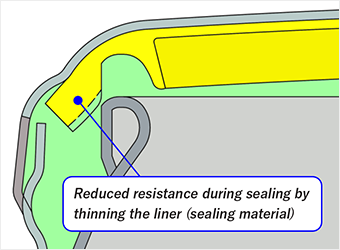

Reduced resistance during closure

We reduced resistance during closure by thinning the liner (resin for sealing the container) on the outside of the fitting section with the bottle. Additionally, by reducing resin usage, we were able to contribute to environmental impact reduction.

Project Review